21

Sep 21How Chemical Blending Equipment Supports Your Success

- September 21, 2021

Enhance and Tailor Your Capabilities and Capacity

Given the nature of the material, it should be no surprise that chemical blending equipment is an essential component of your success in the manufacturing of polyurethane.

Read more

31

Aug 21Polyurethane Safety: 3 Ways to Protect People & Facilities

- August 31, 2021

Utilize Key Solutions to Alleviate Manufacturing Risk

Polyurethane safety is a primary concern for all manufacturers of the versatile material. Needed and used more than ever across virtually every industry in a variety of forms, polyurethane needs to be produced at a high level, in an efficient fashion, and with the needed precautions to avoid risk to the workers and facilities that handle the material every day.

Read more

23

Apr 21Achieving Flexible Polyurethane Foam

- April 23, 2021

Proactive Solutions Needed for Flexible Polyurethane Foam

Flexible polyurethane foam (FPF) is nearly ubiquitous in its use across a wide swath of consumer products. As a polymer produced from the reaction of polyols and isocyanates, FPF is characterized by a cellular structure that allows for some degree of compression and resilience while also providing a cushioning effect.

27

Jan 21Polyurethane Storage: Savings, Safety, Efficiency & More

- January 27, 2021

Put Your Business in a Strong Position to Meet Demand

The new year is here, but unfortunately, the pandemic rages on. While organizations around the world have been able to resume some semblance of normal operations and planning, there remains the possibility of another shift in demand — requiring you to accelerate production to meet your customers’ needs. And should you find yourself in this situation, the last thing you need to be worrying about is polyurethane storage.

16

Dec 20Custom Chemical Mixing: Improve the Bottom Line Via Material Performance

- December 16, 2020

The New Year is Coming — How Will You Improve Your Production Process?

It’s no secret that 2020 has been a challenging year for manufacturers. Regardless of industry, companies around the world have had to tackle new complexities and roadblocks as a result of the pandemic, tariff challenges, and the subsequent supply and logistics hurdles. But from these challenges have come new ways of thinking, innovative new processes, and solutions designed to help companies get back on track — and stay on it.

25

Sep 20The Key to Superior Industrial Strength Foam

- September 25, 2020

Industrial Strength Foam Goes Beyond Industrial Applications

Industrial strength foam isn’t restricted to one or two industries — it’s a common part of multiple industries worldwide. Countless products rely on rigid polyurethane foam as part of their design in order to perform under varying conditions.

16

Apr 20High Strength Foam: 3 Keys to Successful Results

- April 16, 2020

Just About Every Industry Needs High Strength Foam

High strength foam is a core component of numerous industries throughout the world, and for good reason. This type of polyurethane foam is extremely rigid and capable of withstanding abuse in many forms. These include extreme and often rapid temperature variations, sudden impacts and long-term wear, and moisture.

16

Mar 20How Bulk Polyurethane Can Help Grow Your Business

- March 16, 2020

Looking for Cost Efficiency? It’s Time to Consider Bulk Polyurethane

Over the past several years, the polyurethane market has risen consistently in value by around 5 percent annually. The reason for this is due to the benefits of polyurethane itself. As an incredibly lightweight yet durable material, polyurethane is high in demand in numerous industries and markets. Its affordability compared to other more costly materials also makes it a strategic solution for companies looking to maximize margins on their production. But despite these advantages, it’s becoming more and more important to invest in bulk polyurethane.

16

Jan 20Why Invest in Chemical Holding Tanks?

- January 16, 2020

Tired of Those Annoying 55-Gallon Drums and Totes? Go with Chemical Holding Tanks Instead

You’re not alone. For years, companies that manufacture products using polyurethane or that apply polyurethane in other applications have been ordering, hauling, storing, and handling material in 55-gallon drums rather than chemical holding tanks. For companies with more significant production demands, this inefficiency was upsized into significantly larger 270-gallon totes. Depending on overall production volume, companies might have anywhere from dozens to hundreds or even thousands of these drums in their facilities throughout their footprint.

15

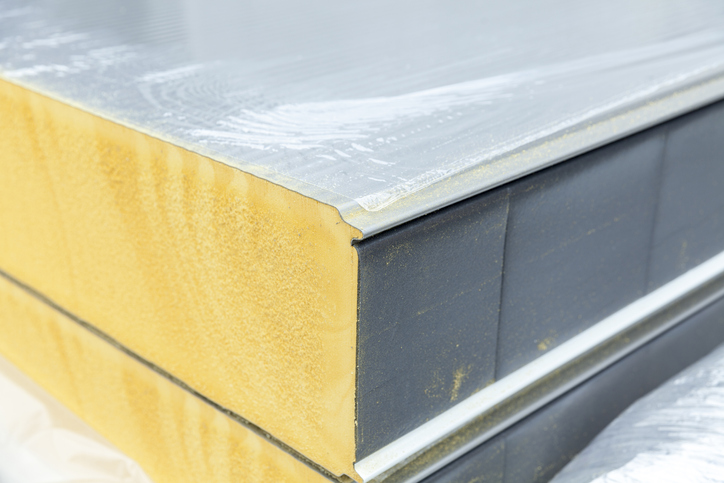

Oct 194 Ways That Bulk Chemical Storage Tanks Improve Productivity

- October 15, 2019

First, What Are Bulk Chemical Storage Tanks?

Bulk chemical storage tanks are far more than just a container for large volumes of polyol and iso. It’s a complete material storage system designed to make your organization’s production facility more streamlined, efficient, sustainable, and cost-effective.