22

Jun 20Ensure Application Success with Polyurethane Testing

- June 22, 2020

Why 2-Step Polyurethane Testing is So Critical for Application Success

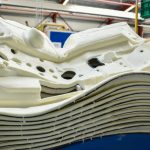

Across the world, polyurethane material is in use in countless products and applications that businesses and consumers need and rely on every day. In each situation, the polyurethane mixture used to create the products must be developed to meet the end product performance characteristics. Chemical suppliers such as Dow, Covestro, and BASF engineer these formulations to address both external pressures from the elements like temperature, moisture, and heat and internal pressure such as cellular structure, composition, any gas nucleation used, and so on. In order to achieve success in these applications, the first step of polyurethane testing is dependent on the chemical suppliers.

18

Feb 20Chemical Metering Systems: The Production Control Center

- February 18, 2020

What Are Chemical Metering Systems?

Whether your organization is in the aerospace, automotive, medical, or sporting goods industry, everything that occurs in your production environment is controlled and regulated in some way. When it comes to polyurethane processing, much of that control is set and monitored by a chemical metering system. These devices control how much material is distributed from a polyurethane storage system (such as a bulk chemical storage tank) to the mix head, where the material is then sprayed, poured, or otherwise distributed onto a specific surface. Chemical metering systems also control key aspects of polyurethane mixing ratios.Read more

- 1

- 2