22

Jun 21Polyurethane Repair: How to Protect Your Investment

- June 22, 2021

Keep Running with Repair, Rebuild, and Replacement Services

With the titanic size of the market, it makes sense for any polyurethane manufacturer, producer, or fabricator to be aware of and employ polyurethane repair services in order to stay up-to-speed with ever-increasing production demands.

Read more

23

Apr 21Achieving Flexible Polyurethane Foam

- April 23, 2021

Proactive Solutions Needed for Flexible Polyurethane Foam

Flexible polyurethane foam (FPF) is nearly ubiquitous in its use across a wide swath of consumer products. As a polymer produced from the reaction of polyols and isocyanates, FPF is characterized by a cellular structure that allows for some degree of compression and resilience while also providing a cushioning effect.

22

Mar 21Polyurethane Services: The Importance of Being Proactive

- March 22, 2021

Being Proactive Matters More Than Ever in Today’s Dynamic Production Environments

With the pandemic came overwhelming uncertainty for many industries, with manufacturing carrying a great deal of it. Innumerable amounts of research have been done on its short- and long-term effects, but it’s clear that even essential operations saw significant upstream and downstream difficulties as suppliers and customers alike were forced to slow down — and in many cases, shut down.

18

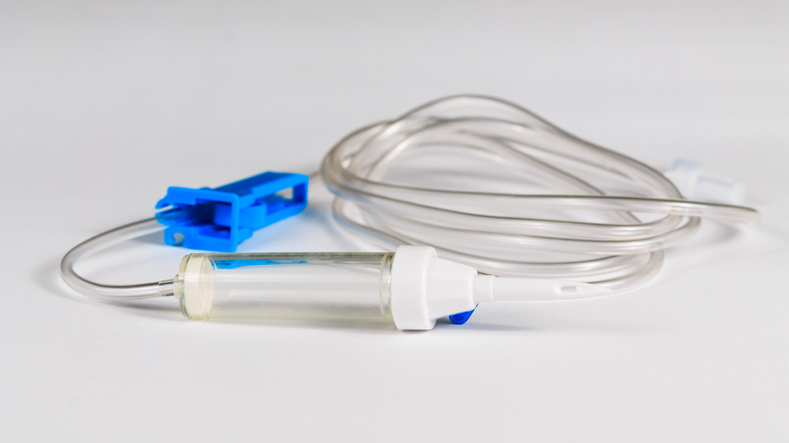

Nov 20Medical Grade Polyurethane: Considerations for Healthy Production

- November 18, 2020

Why the Healthcare Industry Relies on Medical Grade Polyurethane

Polyurethane is one of the most flexible, adaptable, and customizable materials in use in countless applications and markets today. From being used in the military for numerous defense applications due to its strength and affordability to serving as a structural component in the construction industry due to its rigidity and sound absorption properties, there’s no other material like polyurethane. The same goes for healthcare and pharmaceutical, where medical grade polyurethane is used for countless applications.Read more

25

Sep 20The Key to Superior Industrial Strength Foam

- September 25, 2020

Industrial Strength Foam Goes Beyond Industrial Applications

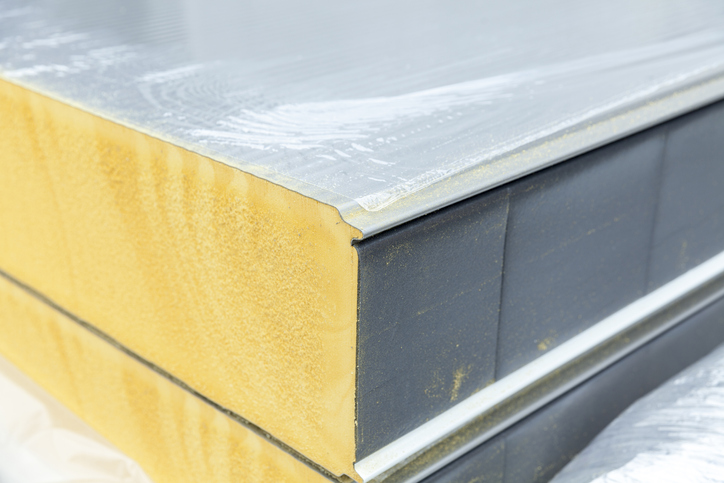

Industrial strength foam isn’t restricted to one or two industries — it’s a common part of multiple industries worldwide. Countless products rely on rigid polyurethane foam as part of their design in order to perform under varying conditions.

22

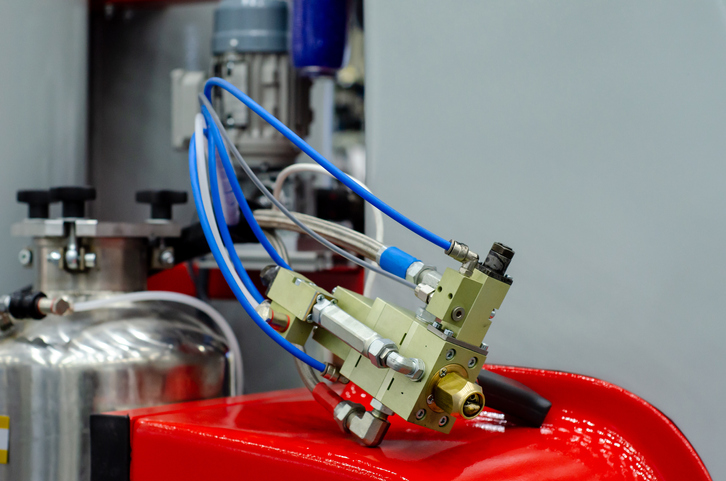

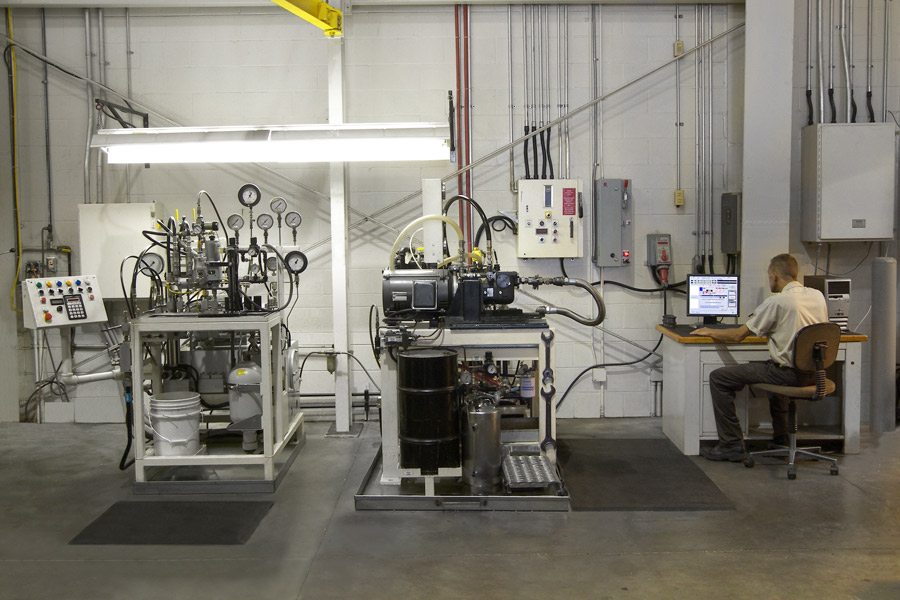

Jun 20Ensure Application Success with Polyurethane Testing

- June 22, 2020

Why 2-Step Polyurethane Testing is So Critical for Application Success

Across the world, polyurethane material is in use in countless products and applications that businesses and consumers need and rely on every day. In each situation, the polyurethane mixture used to create the products must be developed to meet the end product performance characteristics. Chemical suppliers such as Dow, Covestro, and BASF engineer these formulations to address both external pressures from the elements like temperature, moisture, and heat and internal pressure such as cellular structure, composition, any gas nucleation used, and so on. In order to achieve success in these applications, the first step of polyurethane testing is dependent on the chemical suppliers.

16

Mar 20How Bulk Polyurethane Can Help Grow Your Business

- March 16, 2020

Looking for Cost Efficiency? It’s Time to Consider Bulk Polyurethane

Over the past several years, the polyurethane market has risen consistently in value by around 5 percent annually. The reason for this is due to the benefits of polyurethane itself. As an incredibly lightweight yet durable material, polyurethane is high in demand in numerous industries and markets. Its affordability compared to other more costly materials also makes it a strategic solution for companies looking to maximize margins on their production. But despite these advantages, it’s becoming more and more important to invest in bulk polyurethane.